Here are 20 key interview questions for a Customer Quality Manager role, along with example answers. These responses showcase leadership, technical knowledge, and a customer-focused approach.

1. What is your process to handle a customer complaint?

Answer: My process starts with listening to the customer to understand their complaint fully, ensuring I gather all necessary details. I then conduct a thorough root cause analysis with the team, implement corrective actions, and communicate transparently with the customer throughout the process. Finally, I follow up to ensure the customer is satisfied with the resolution and to identify any additional improvement opportunities.

2. What tools and techniques do you use to solve customer quality issues?

Answer: I use quality management tools like Root Cause Analysis (RCA), Failure Mode and Effects Analysis (FMEA), and Six Sigma to identify issues and prevent recurrence. I also employ statistical tools for process control and rely on corrective and preventive action (CAPA) systems to monitor quality improvements effectively. These tools enable data-driven decision-making and enhance product reliability.

3. Describe a time when you improved quality standards to meet customer expectations.

Answer: In my previous role, a key customer raised concerns about product durability. I led a team to reassess material selection and production processes, working closely with R&D to enhance quality standards. After implementing these changes, we observed a significant decrease in complaints and an increase in customer satisfaction, proving that our improvements aligned with customer expectations.

4. How do you prioritize customer complaints or quality issues when there are multiple at the same time?

Answer: I prioritize based on factors like safety risks, impact on customer operations, and complaint recurrence. Critical or high-risk issues are addressed immediately, while others are scheduled according to severity and impact on our business. This prioritization ensures that our focus remains on high-impact areas while maintaining overall quality standards.

5. Can you give an example of a recent customer complaint and how you resolved it?

Answer: Recently, a major customer reported frequent defects in one of our high-volume parts. After performing a root cause analysis, we discovered a calibration issue with the machinery. We quickly corrected it and enhanced our inspection process to prevent future issues. I also kept the customer informed throughout and followed up to confirm their satisfaction with the product after the changes, which helped rebuild trust.

6. What types of customers have you handled?

Answer: I have experience handling customers across various sectors, including automotive, heavy machinery, and consumer electronics. Each sector has unique requirements and expectations regarding quality and reliability. This experience has enabled me to adapt my quality management practices to meet diverse customer needs effectively.

7. How do you communicate quality issues to customers effectively?

Answer: I ensure that communication is clear, honest, and solution-oriented. When a quality issue arises, I provide the customer with an overview of the issue, a timeline for resolution, and detailed information on corrective actions. By involving them in the process and keeping them informed, I maintain transparency and help reinforce their confidence in our commitment to quality.

8. What strategies do you use to collaborate with other departments on quality issues?

Answer: I regularly engage with departments like production, R&D, and supply chain to discuss ongoing quality issues, share customer feedback, and implement process improvements. Holding cross-functional meetings ensures everyone is aligned and that quality improvements are incorporated from design to production, reducing the likelihood of recurring issues.

9. How do you measure customer satisfaction in relation to quality?

Answer: I use customer satisfaction surveys, Net Promoter Score (NPS), and metrics like complaint frequency and resolution time. Additionally, I monitor repeat complaints and request regular feedback from customers. These insights help gauge satisfaction levels and inform continuous improvement efforts to ensure our quality aligns with customer expectations.

10. How do you handle a situation where a customer’s quality expectations exceed industry standards?

Answer: I first analyze the feasibility of meeting the customer’s expectations and the associated costs. If meeting these standards is possible and beneficial, I work with internal teams to adapt our processes accordingly. If not feasible, I discuss alternatives or customization options with the customer, ensuring we reach a practical, mutually beneficial solution.

11. Can you explain the 8D problem-solving steps?

Answer: The 8D (Eight Disciplines) problem-solving method is a structured approach commonly used in quality management to address complex problems:

- D1: Establish the Team – Form a cross-functional team with the necessary knowledge.

- D2: Define the Problem – Clearly describe the problem with data and specifics.

- D3: Develop Interim Containment Actions – Implement temporary actions to protect the customer.

- D4: Identify Root Causes – Use tools like Root Cause Analysis to find underlying issues.

- D5: Develop Permanent Corrective Actions – Plan and implement long-term solutions.

- D6: Implement and Validate Corrective Actions – Test and confirm the effectiveness of solutions.

- D7: Prevent Recurrence – Update procedures or standards to avoid similar issues.

- D8: Recognize the Team – Acknowledge the team’s effort in resolving the issue.

12. How do you handle challenging or demanding customers?

Answer: I approach challenging customers with patience and empathy, ensuring they feel heard and respected. I remain calm and solution-focused, working collaboratively to address their concerns and providing them with realistic timelines and regular updates. This approach usually turns around even the most challenging interactions.

13. Describe your experience with quality audits. How do you prepare for them?

Answer: I have conducted and prepared for internal and external quality audits, ensuring compliance with industry standards and customer specifications. Preparation includes reviewing all documentation, verifying process adherence, and conducting pre-audit checks. I also brief the team on potential improvement areas and ensure readiness for any inquiries auditors may have.

14. What methods do you use to gather feedback from customers on quality?

Answer: I use various methods, including surveys, regular check-in calls, and post-issue follow-ups, to gather feedback. Additionally, I analyze complaint patterns, customer reviews, and Net Promoter Scores (NPS). This data helps us gauge satisfaction levels and refine our quality practices.

15. Can you share an instance where your quality improvements directly impacted customer satisfaction?

Answer: In my previous role, customers had frequent complaints about a specific product’s durability. By leading a project to enhance material quality and collaborating with production to improve consistency, we significantly reduced complaints. This improvement was directly reflected in higher customer satisfaction ratings and an increase in repeat business.

16. How do you track the effectiveness of corrective actions?

Answer: I track corrective actions using metrics such as defect rate reduction, complaint frequency, and reoccurrence of similar issues. Additionally, I review any performance feedback from customers and monitor related KPIs. This helps us assess whether our corrective actions are genuinely effective or need further refinement.

17. How do you handle a quality issue that affects multiple customers simultaneously?

Answer: I prioritize containment actions to prevent further impact and communicate transparently with affected customers. Then, I lead a rapid root cause analysis with a cross-functional team and implement corrective actions. I keep customers updated on progress and resolution steps, demonstrating our commitment to quality and customer care.

18. What quality management tools do you find most useful in your role, and why?

Answer: Tools like Root Cause Analysis (RCA), Failure Mode and Effects Analysis (FMEA), and Six Sigma are invaluable. RCA helps identify the underlying issues, FMEA allows us to assess potential risks, and Six Sigma improves process efficiency. These tools enable data-driven decisions and sustainable quality improvements.

19. Describe a time when you had to deal with a recurring quality issue. How did you address it?

Answer: In one case, we experienced recurring defects in a specific component. After a detailed analysis, I found that variability in raw material was the root cause. I worked with suppliers to establish stricter quality controls and updated our internal testing protocols. This eliminated the issue, improving product reliability and customer satisfaction.

20. How do you ensure that corrective and preventive actions are embedded in the team’s daily processes?

Answer: I integrate corrective and preventive actions into our standard operating procedures and provide team training to ensure they understand the importance of these actions. Regular follow-up audits and performance checks reinforce adherence, and I foster a culture of continuous improvement, encouraging team members to actively participate in maintaining quality standards.

These answers highlight the structured approach, technical skills, and customer-focused strategies required for a Customer Quality Manager role, making them highly relevant for interview preparation.

- Top 15 MNCs Every Mechanical Engineer Dreams of Joining in 2025

- How to Digitize and Automate the CAPA Process

- Top 10 Essential Tools Every Mechanical Engineer Should Know

- What is GD&T (Geometric Dimensioning & Tolerancing) ?

- Principles of IATF 16949: A Guide to Quality Management

- The Evolution of IATF 16949: The Automotive Quality Standard

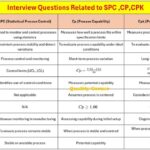

- Top Interview Questions Related to SPC ,Cp and Cpk

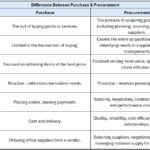

- Difference Between Purchase and Procurement

- Master Your Job Interview: Top 70 Common Interview Questions and Answers

- What Is Standard Deviation ?

- Top Interview Questions and Answers on SPC

- Top 20 Interview Questions For Customer Quality Manager ?