Takt Time Calculator

Takt time is a key metric in manufacturing and production that represents the maximum amount of time in which a product must be produced to meet customer demand. It helps synchronize production pace with the rate of customer orders, ensuring a balanced and efficient workflow. The term “takt” comes from the German word for “rhythm” or “beat,” reflecting the need to maintain a steady production pace.

Takt time is calculated using the following formula:

Where:

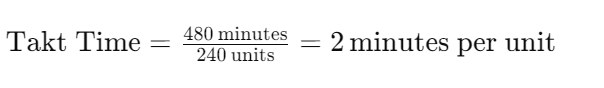

For example, if a factory operates for 8 hours a day (480 minutes) and the customer demand is 240 units per day, the takt time would be:

This means the factory should produce one unit every 2 minutes to meet customer demand.

Takt time is an essential concept in lean manufacturing and helps in:

By monitoring and adjusting to the takt time, manufacturers can optimize their processes, reduce waste, and enhance overall productivity.