Statistical Process Control (SPC) is an essential aspect of quality assurance in manufacturing industries. Professionals working in quality roles, especially in steel, automobile, or any manufacturing sector, should be well-versed with SPC concepts like Cp, Cpk, and Ppk. If you’re preparing for an interview, these SPC interview questions related to SPC will help you tackle real-world scenarios and showcase your practical knowledge. Let’s dive into the detailed questions, explanations, and additional insights.

Table of Contents

- What is SPC?

- Understanding Cp and Cpk

- Common Interview Questions on Cp and Cpk

- Practical Scenarios and Solutions

- Key Differences Between Cp and Cpk

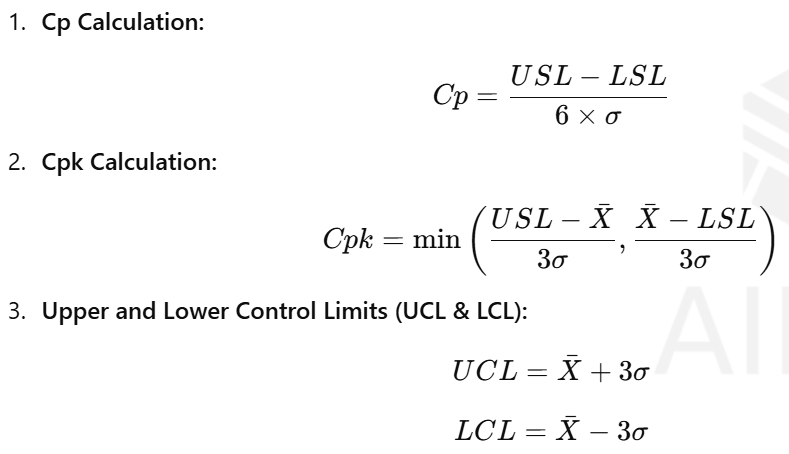

- Essential Formulas and Calculations

- Advanced SPC Questions for Experienced Candidates

1. What is SPC?

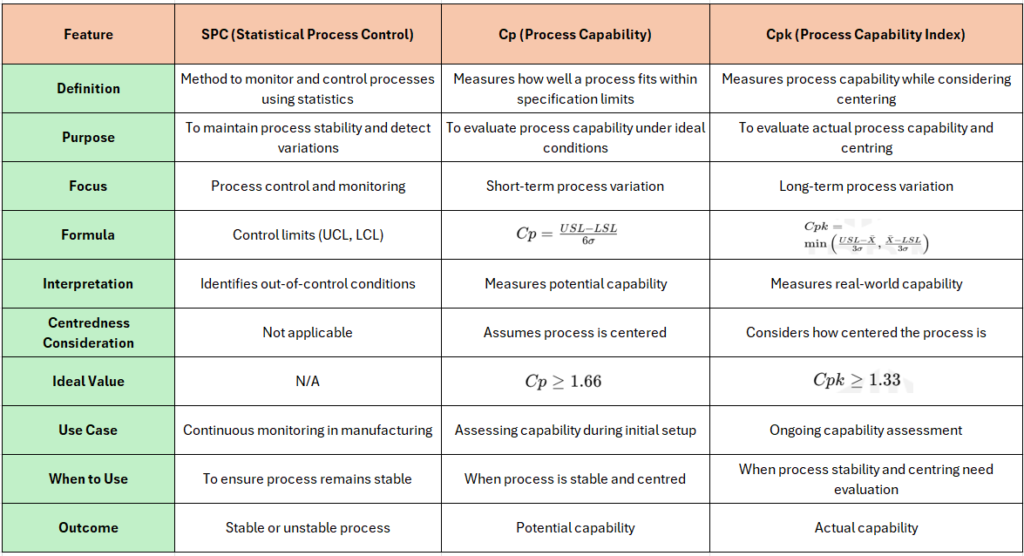

SPC (Statistical Process Control) is a method used to monitor, control, and improve a process through statistical analysis. It helps ensure that the process remains within defined limits and produces consistent quality.

2. Understanding Cp and Cpk

- Cp (Process Capability):

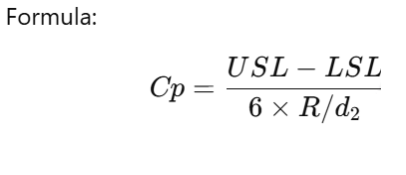

Cp measures how well the process can produce items within specification limits under ideal conditions (short-term capability).

- Where:

- USL: Upper Specification Limit

- LSL: Lower Specification Limit

- R: Range

- d2: Constant based on sample size

- Cpk (Process Capability Index):

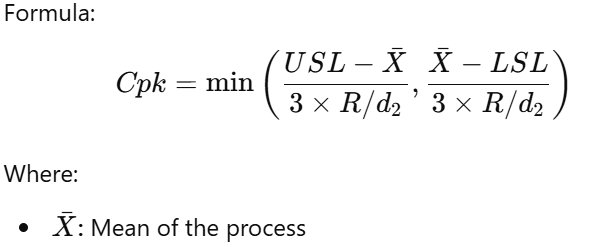

Cpk evaluates both the spread and the centeredness of the process relative to the specification limits (long-term capability).

3. Common Interview Questions on Cp and Cpk

- What is the difference between Cp and Cpk?

- Answer:

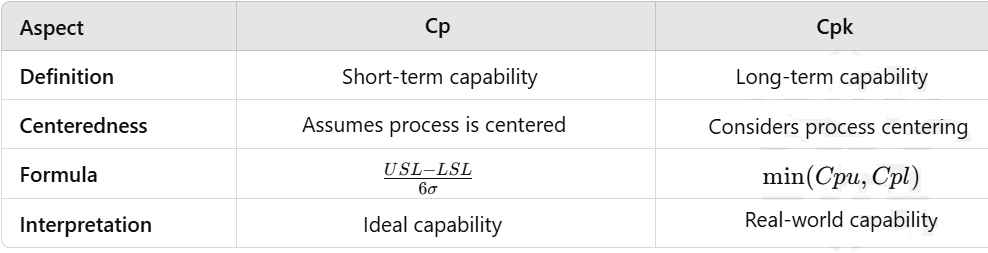

Cp measures process capability assuming the process is perfectly centred, whereas Cpk considers how centred the process is relative to the specification limits.

- Answer:

- When is Cp equal to Cpk?

- Answer:

Cp equals Cpk when the process is perfectly centred between the specification limits.

- Answer:

- What does it mean if Cpk is less than 1?

- Answer:

If Cpk < 1, the process is not capable of meeting customer specifications, and corrective actions are needed to improve capability.

- Answer:

- What action should be taken if Cpk < 1.33?

- Answer:

If Cpk < 1.33, the process needs some improvement to meet specifications reliably. This could involve reducing variation or re-centering the process.

- Answer:

- Why is Ppk different from Cpk?

- Answer:

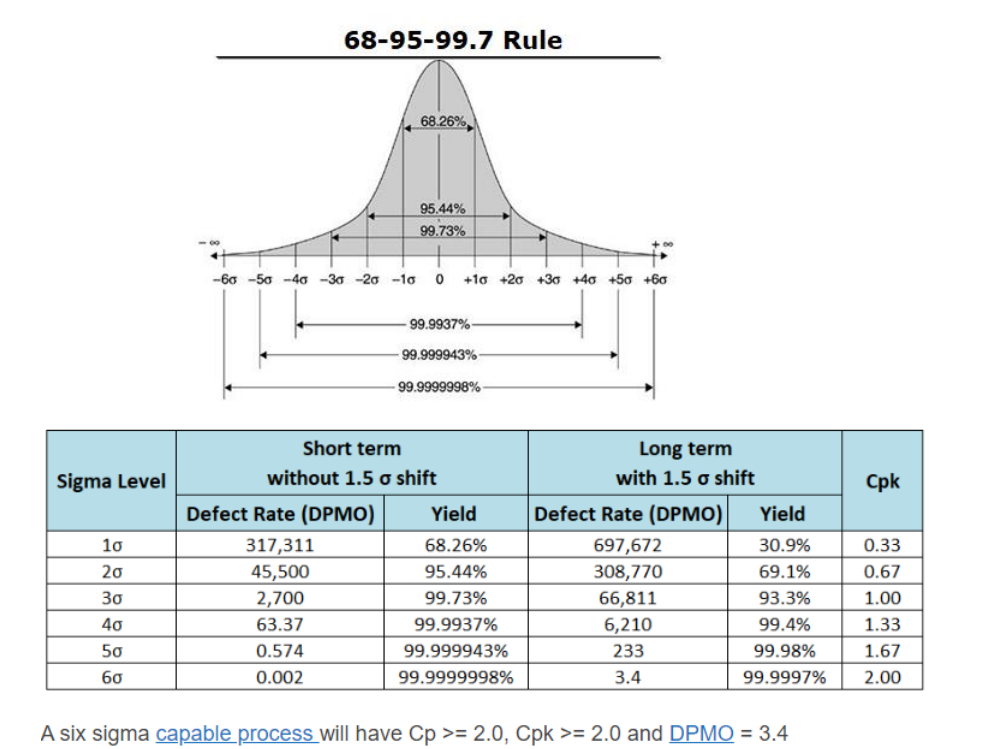

- Cpk measures process capability based on sample data (short-term).

- Ppk (Process Performance Index) evaluates long-term process capability considering the overall variation in the entire process.

- Answer:

- What is the ideal value of Cpk for a capable process?

- Answer:

A Cpk value of 1.66 or higher indicates a good process capability.

- Answer:

- What does a negative Ppk value indicate?

- Answer:

A negative Ppk means the process mean is outside the specification limits, indicating severe issues in the process.

- Answer:

4. Practical Scenarios and Solutions

- Scenario:

The Cpk value for a critical component in your manufacturing process is 1.1. What steps would you take? Solution:- Conduct a detailed analysis to identify sources of variation.

- Check for any process drift or out-of-control conditions.

- Re-canter the process if necessary or reduce variation through Six Sigma techniques.

- Scenario:

Your process shows Cp = 1.5 but Cpk = 1.0. What does this imply? Solution:- This indicates the process is capable, but it is not centred properly. Work on adjusting the process mean closer to the specification midpoint.

5. Key Differences Between Cp and Cpk

6. Essential Formulas and Calculations

7. Advanced SPC Questions for Experienced Candidates

- How do you handle a process where the Cpk is consistently fluctuating?

- Explain the importance of control charts in SPC. Which control charts do you typically use for variable data?

- Describe a situation where you improved process capability in your previous role.

- How do you determine the sample size for an SPC study?

Conclusion

Mastering SPC concepts like Cp, Cpk, and Ppk is critical for quality assurance roles. These SPC interview questions related to SPC are designed to help you not only prepare for interviews but also understand how to apply these concepts in real-world scenarios. Ensure you are familiar with the calculations, interpretations, and corrective actions to ace your next interview.

Further Reading

- Understanding Statistical Process Control (SPC) – ASQ: Introduction to SPC

- In-depth Guide on Process Capability and Cpk – iSixSigma: Process Capability Indices

- What Is Standard Deviation ?

- Top 15 MNCs Every Mechanical Engineer Dreams of Joining in 2025

- How to Digitize and Automate the CAPA Process

- Top 10 Essential Tools Every Mechanical Engineer Should Know

- What is GD&T (Geometric Dimensioning & Tolerancing) ?

- Principles of IATF 16949: A Guide to Quality Management

- The Evolution of IATF 16949: The Automotive Quality Standard