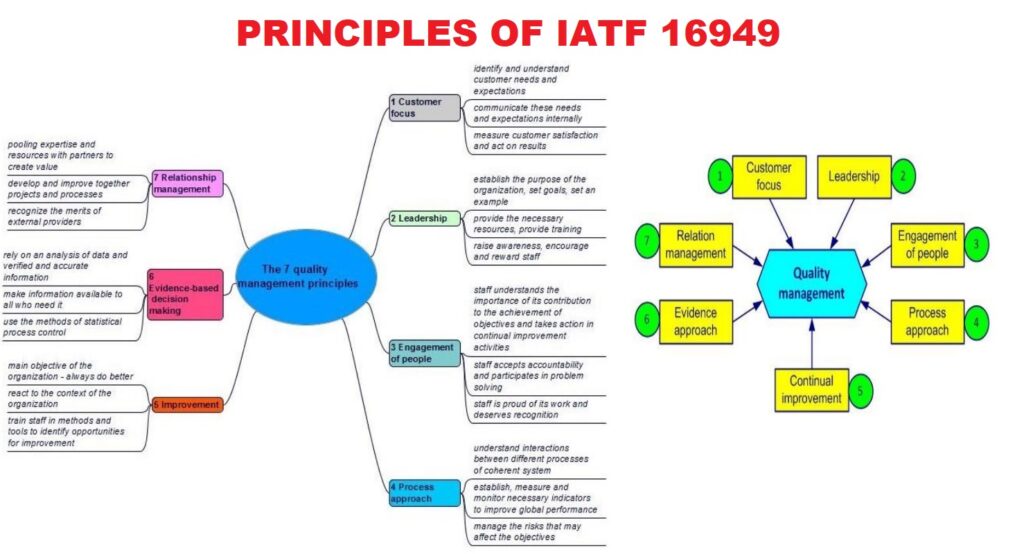

The Principles of IATF 16949 are essential for achieving excellence in the automotive industry. IATF 16949 is an international standard for quality management systems (QMS), specifically designed for automotive manufacturers and suppliers. This standard combines essential quality principles that help companies meet customer requirements, improve processes, and ensure continuous improvement.

In this article, we will explain the 7 principles of IATF 16949, their significance, and how they drive quality management. The focus keyword “Principles of IATF 16949” will guide you through everything you need to know to enhance your organization’s performance.

What are the 7 Principles of IATF 16949?

The IATF 16949 standard is based on 7 core quality management principles. These principles help businesses maintain a customer-focused approach, foster leadership, and promote continual improvement. Below are the 7 principles:

- Customer Focus

- Leadership

- Engagement of People

- Process Approach

- Continual Improvement

- Evidence-Based Decision Making

- Relationship Management

Each principle plays a key role in enhancing processes, increasing efficiency, and ensuring customer satisfaction. Let’s discuss these in detail.

1. Customer Focus

Customer focus is the first principle of IATF 16949. Organizations must understand and fulfill customer needs to achieve long-term success.

Key Actions:

- Identify and understand customer needs and expectations.

- Communicate customer requirements within the organization.

- Measure and act on customer satisfaction results.

By prioritizing customers, businesses can build trust and create long-term value.

2. Leadership

Effective leadership drives the success of any quality management system. Leadership sets the vision and creates a culture that fosters growth and collaboration.

Key Actions:

- Establish a clear purpose and organizational goals.

- Provide resources, training, and support to staff.

- Motivate, reward, and encourage employees to achieve objectives.

Leaders must lead by example to inspire teams to meet organizational goals.

3. Engagement of People

The third principle of IATF 16949 emphasizes the importance of involving employees at all levels. Engaged people are more committed, productive, and innovative.

Key Actions:

- Encourage accountability and ownership among staff.

- Recognize and reward employee contributions.

- Promote problem-solving and teamwork.

When employees understand their role, they take actions that improve performance.

4. Process Approach

Organizations must focus on managing processes systematically. The process approach improves consistency, efficiency, and overall performance.

Key Actions:

- Identify and understand interactions between different processes.

- Measure and monitor performance indicators.

- Manage risks to achieve objectives effectively.

This principle ensures a streamlined, cohesive system that avoids silos.

5. Continual Improvement

Continual improvement is at the core of quality management systems. Organizations must always strive to improve their products, processes, and systems.

Key Actions:

- React to changes in the business environment.

- Train staff to identify improvement opportunities.

- Adopt tools and methods that foster innovation.

Continual improvement ensures that organizations remain competitive and efficient.

6. Evidence-Based Decision Making

Decisions based on data and analysis yield better results. The sixth principle of IATF 16949 focuses on making decisions with reliable information.

Key Actions:

- Analyze data and verified information for decision-making.

- Use statistical tools for process control.

- Share data with teams to improve transparency.

Data-driven decisions improve accuracy and reduce errors.

7. Relationship Management

Strong relationships with stakeholders, including suppliers, partners, and customers, are vital for success. Collaboration creates value for everyone involved.

Key Actions:

- Work together with partners to achieve mutual goals.

- Recognize and value the contribution of external providers.

- Develop and improve processes collectively.

Building long-term relationships promotes trust, reliability, and shared success.

Benefits of Following the Principles of IATF 16949

The Principles of IATF 16949 are designed to help organizations:

- Improve product and process quality.

- Enhance customer satisfaction.

- Reduce operational inefficiencies and waste.

- Boost employee engagement and accountability.

- Ensure continual growth through systematic improvement.

By implementing these principles, businesses gain a competitive edge in the global automotive industry.

Final Thoughts

The Principles of IATF 16949 serve as the foundation of an effective quality management system. By following these 7 principles—Customer Focus, Leadership, Engagement of People, Process Approach, Continual Improvement, Evidence-Based Decision Making, and Relationship Management—organizations can improve performance, reduce risks, and meet customer expectations.

Related Resources:

For more insights on quality management and international standards, check out:

- IATF 16949 Standard Overview

- ISO 9001 vs IATF 16949 Explained

- The Evolution of IATF 16949: The Automotive Quality Standard

Implementing these principles will help your organization achieve excellence and ensure long-term success. Start building a culture of quality today!

Read Similar Articles :

- Top 15 MNCs Every Mechanical Engineer Dreams of Joining in 2025

- How to Digitize and Automate the CAPA Process

- Top 10 Essential Tools Every Mechanical Engineer Should Know

- What is GD&T (Geometric Dimensioning & Tolerancing) ?

- Principles of IATF 16949: A Guide to Quality Management

- The Evolution of IATF 16949: The Automotive Quality Standard

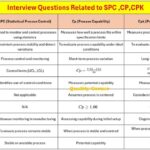

- Top Interview Questions Related to SPC ,Cp and Cpk

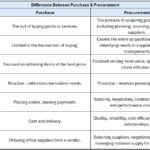

- Difference Between Purchase and Procurement

- Master Your Job Interview: Top 70 Common Interview Questions and Answers