OEE Calculator

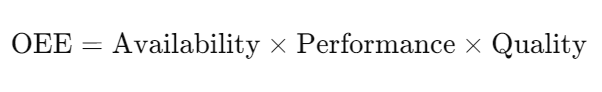

Overall Equipment Effectiveness (OEE) is a key performance indicator used in manufacturing to measure the efficiency and effectiveness of a production process. It provides a comprehensive view of how well manufacturing equipment is utilized compared to its full potential. OEE considers three factors: availability, performance, and quality.

The formula for calculating OEE is:

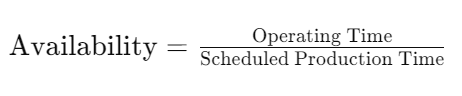

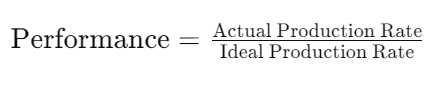

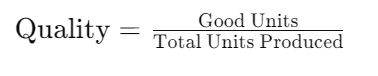

Each component is calculated as follows:

- Availability: Measures the percentage of scheduled time that the equipment is available for production.

- Performance: Measures how well the equipment performs compared to its maximum possible speed.

- Quality: Measures the percentage of good units produced out of the total units started.

To calculate OEE, follow these steps:

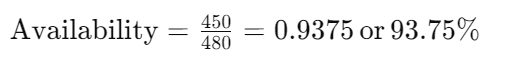

- Calculate Availability: If the equipment was scheduled to run for 8 hours (480 minutes) but was down for 30 minutes, the operating time is 450 minutes. Availability is:

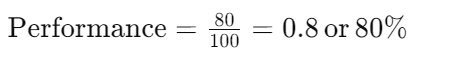

- Calculate Performance: If the ideal production rate is 100 units per hour (1.67 units per minute) and the actual production rate is 80 units per hour, performance is:

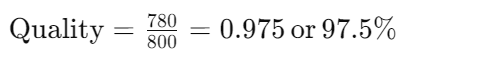

- Calculate Quality: If 780 good units were produced out of 800 total units, quality is:

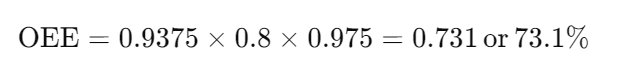

- Calculate OEE: Multiply the three factors together:

An OEE score of 100% represents perfect production: manufacturing only good parts, as fast as possible, with no downtime. By tracking OEE, companies can identify areas for improvement and enhance overall productivity.