ISO 9001 and IATF 16949 are both quality management system standards, but they have different scopes and requirements tailored to different industries.

ISO 9001:

Scope:

- ISO 9001 is a general quality management standard applicable to any organization, regardless of its type, size, or the products/services it provides.

Purpose:

- It provides a framework for consistent quality management practices aimed at improving overall customer satisfaction and continuous improvement.

Key Features:

- Focus on customer satisfaction.

- Emphasis on leadership and management commitment.

- Risk-based thinking to enhance the process approach.

- Continuous improvement through the Plan-Do-Check-Act (PDCA) cycle.

- Applicability across various sectors and industries.

Structure:

- Consists of requirements that help organizations establish, implement, maintain, and improve a quality management system.

IATF 16949:

Scope:

- IATF 16949 is a technical specification specifically designed for the automotive industry.

Purpose:

- It aims to harmonize the different assessment and certification systems in the global automotive supply chain.

- Focuses on defect prevention, continuous improvement, and the reduction of variation and waste in the automotive industry.

Key Features:

- Integrates with ISO 9001, but includes additional automotive-specific requirements.

- Emphasis on product safety and conformity.

- Requirements for embedded software.

- Supplier development and management.

- More stringent requirements on risk management and contingency planning.

- Traceability throughout the supply chain.

Structure:

- Based on ISO 9001 structure but with additional automotive-specific clauses.

- Organizations must be certified to ISO 9001 as a base, and then to IATF 16949.

Summary:

- ISO 9001 is a versatile quality management system standard suitable for any organization.

- IATF 16949 is specifically tailored for the automotive sector, building on ISO 9001 with additional requirements to address industry-specific needs.

Organizations in the automotive sector often use both standards to ensure comprehensive quality management and meet the specific demands of their industry.

Download Editable Excel Template For IATF & ISO

For similar articles click below:

- Top 15 MNCs Every Mechanical Engineer Dreams of Joining in 2025

- How to Digitize and Automate the CAPA Process

- Top 10 Essential Tools Every Mechanical Engineer Should Know

- What is GD&T (Geometric Dimensioning & Tolerancing) ?

- Principles of IATF 16949: A Guide to Quality Management

- The Evolution of IATF 16949: The Automotive Quality Standard

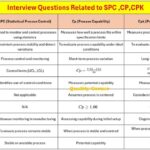

- Top Interview Questions Related to SPC ,Cp and Cpk

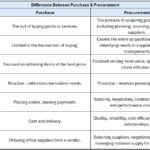

- Difference Between Purchase and Procurement

- Master Your Job Interview: Top 70 Common Interview Questions and Answers

- What Is Standard Deviation ?

- Top Interview Questions and Answers on SPC

- Top 20 Interview Questions For Customer Quality Manager ?