Introduction to IATF 16949

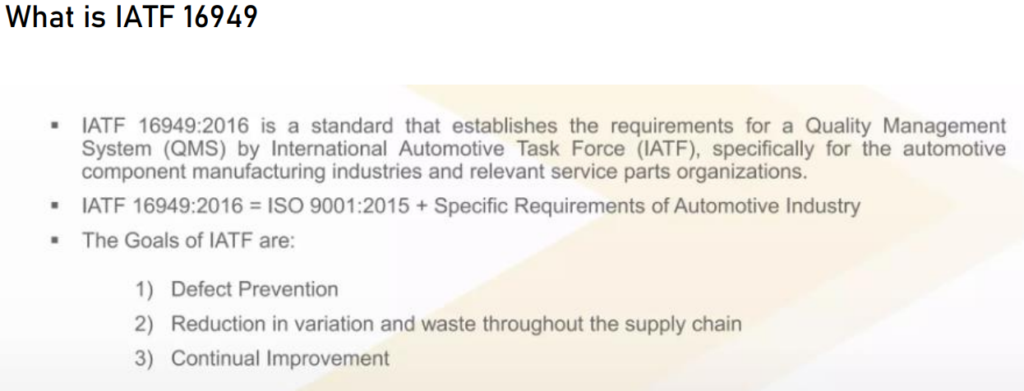

The IATF 16949 standard is a globally recognized certification for Quality Management Systems (QMS) specific to the automotive industry. Created by the International Automotive Task Force (IATF), this standard aligns with ISO 9001:2015 and includes additional requirements tailored to automotive production and service parts organizations.

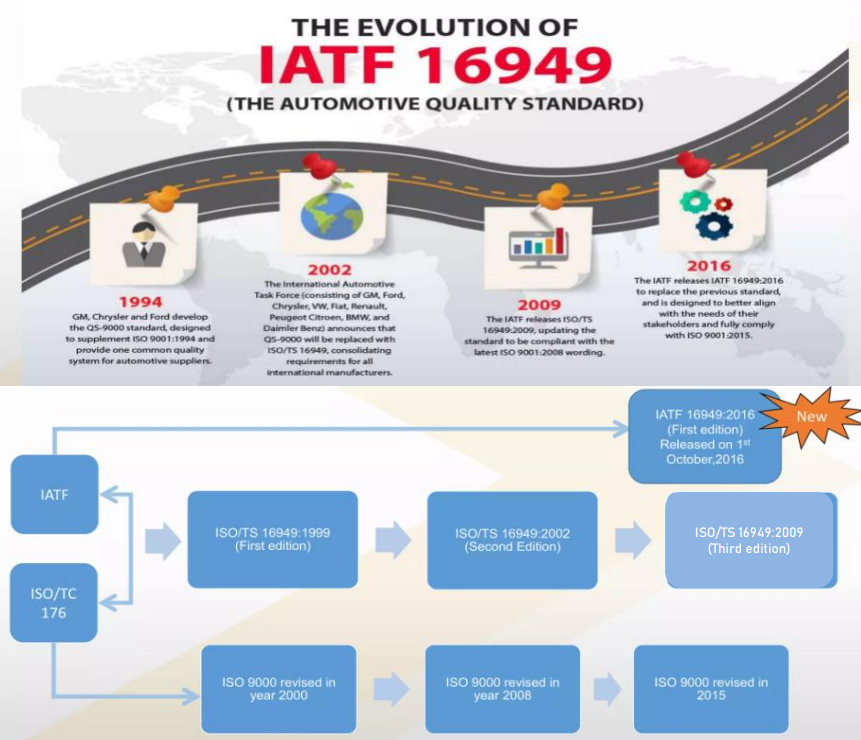

Since its inception in 1999, IATF 16949 has undergone several revisions to address evolving industry needs. The standard focuses on defect prevention, reducing variation, and promoting continual improvement throughout the automotive supply chain.

In this article, we’ll explore the history, reasons for change, and key benefits of IATF 16949 to understand its pivotal role in enhancing automotive quality standards.

History of IATF 16949

Initial Development in 1999

The first edition of IATF 16949, known as ISO/TS 16949:1999, was developed in 1999 by the International Automotive Task Force (IATF). The goal was to harmonize the different assessment and certification systems used worldwide in the automotive industry. This standard combined ISO 9001 principles with additional automotive-specific requirements.

2002: Second Edition

In 2002, the second edition of ISO/TS 16949 was introduced. This revision accounted for enhancements in the automotive sector and updates to ISO 9001:2000. It continued to focus on aligning quality management practices across global automotive suppliers.

2009: Third Edition

The third edition, released in 2009, aligned with ISO 9001:2008. This version emphasized process-oriented quality management, defect prevention, and continuous improvement. The changes were driven by feedback from industry stakeholders, including original equipment manufacturers (OEMs), suppliers, and certification bodies.

2016: Transition to IATF 16949:2016

In October 2016, the IATF 16949:2016 standard replaced ISO/TS 16949:2009. This new version is not a stand-alone QMS standard but must be implemented alongside ISO 9001:2015. It incorporates additional requirements specific to the automotive industry while maintaining alignment with ISO 9001 standards.

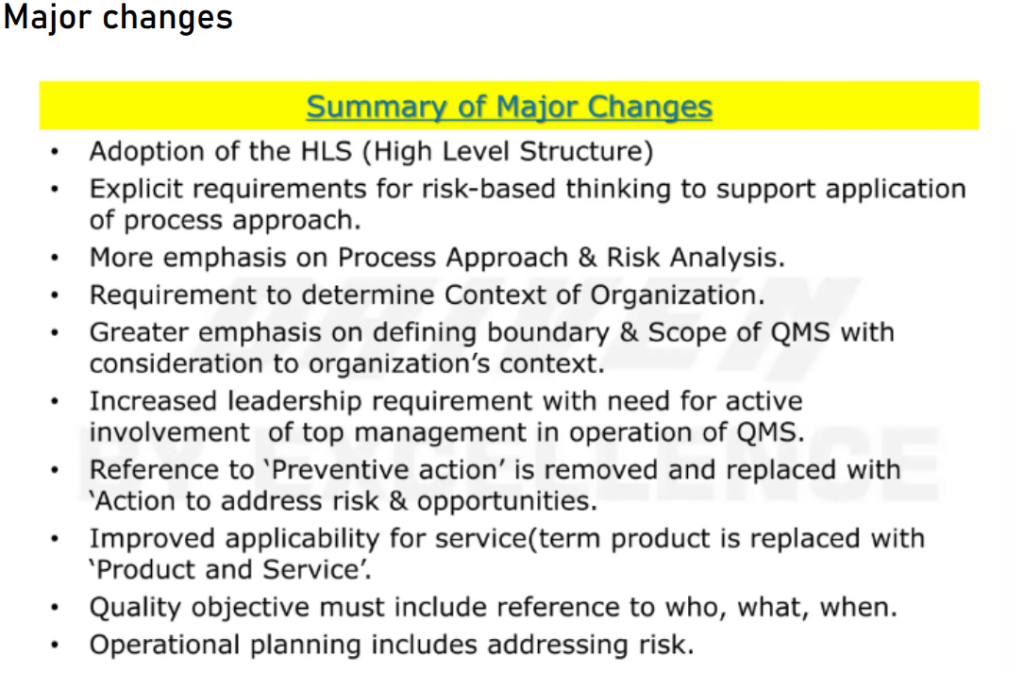

Key improvements in IATF 16949:2016 include:

- Enhanced focus on risk management and defect prevention.

- Requirements for product safety and embedded software.

- Stronger emphasis on customer-specific requirements.

- Clearer guidelines on supplier development and management.

Why the Change from ISO/TS 16949 to IATF 16949?

The transition from ISO/TS 16949:2009 to IATF 16949:2016 was necessary to address several factors:

- Alignment with ISO 9001:2015: The new standard aligns with the revised ISO 9001:2015, incorporating a risk-based approach and improved process efficiency.

- Industry-Specific Enhancements: The IATF identified the need for automotive-specific enhancements, such as stricter requirements for defect prevention and supplier management.

- Global Standardization: The IATF aimed to provide a unified standard for automotive manufacturers and suppliers worldwide, ensuring consistency in quality management practices.

Organizations seeking IATF 16949 certification must also comply with ISO 9001:2015, making the two standards interconnected and essential for maintaining quality in the automotive supply chain.

Goals and Benefits of IATF 16949

The primary goals of IATF 16949 are:

- Defect Prevention: Emphasizing proactive measures to prevent defects rather than correcting them after they occur.

- Reduction of Variation and Waste: Minimizing inconsistencies and waste throughout the supply chain to improve efficiency and product quality.

- Continual Improvement: Promoting an ongoing commitment to quality enhancement and customer satisfaction.

Benefits of implementing IATF 16949 include:

- Improved product quality and reliability.

- Enhanced customer satisfaction through consistent delivery of high-quality products.

- Greater efficiency in processes, reducing costs associated with defects and waste.

- Increased credibility and marketability for suppliers in the automotive industry.

Key Industries and Applicability

IATF 16949 applies specifically to organizations involved in the production of automotive components and related service parts. These include:

- Cars

- Light commercial vehicles

- Trucks

- Buses

- Motorcycles

However, it excludes industries such as:

- Industrial equipment

- Agricultural machinery

- Off-highway vehicles

- Aftermarket parts

For organizations involved in these sectors, alternative standards may apply.

Implementing IATF 16949

Implementing IATF 16949 requires organizations to:

- Understand ISO 9001:2015: Since IATF 16949 supplements ISO 9001:2015, a thorough understanding of this standard is crucial.

- Engage Leadership: Strong commitment from top management ensures successful implementation and continuous improvement.

- Focus on Risk Management: Identifying and mitigating risks in the supply chain is essential to meet IATF 16949 requirements.

- Develop Supplier Relationships: Effective supplier management is critical to maintaining quality standards throughout the supply chain.

Conclusion

The evolution of IATF 16949 represents a continuous commitment to quality, efficiency, and customer satisfaction within the automotive industry. From its inception as ISO/TS 16949 in 1999 to the latest version, IATF 16949:2016, this standard has consistently adapted to industry needs and technological advancements.

Organizations that implement IATF 16949 not only achieve defect prevention and waste reduction but also position themselves as reliable partners in the global automotive supply chain. As the industry evolves, adherence to IATF 16949 will remain critical for maintaining quality excellence.

For more details on the implementation process, visit IATF’s official website for resources and guidance.

For further reading on quality management and standards, check out the following resources:

- What is the difference between ISO 9001 and IATF 16949 ?

- International Automotive Task Force (IATF) Website

Click Below For Similar Articles:

- Top 15 MNCs Every Mechanical Engineer Dreams of Joining in 2025

- How to Digitize and Automate the CAPA Process

- Top 10 Essential Tools Every Mechanical Engineer Should Know

- What is GD&T (Geometric Dimensioning & Tolerancing) ?

- Principles of IATF 16949: A Guide to Quality Management

- The Evolution of IATF 16949: The Automotive Quality Standard

- Top Interview Questions Related to SPC ,Cp and Cpk

- Difference Between Purchase and Procurement

- Master Your Job Interview: Top 70 Common Interview Questions and Answers